Starn Tool & MFG Capabilities

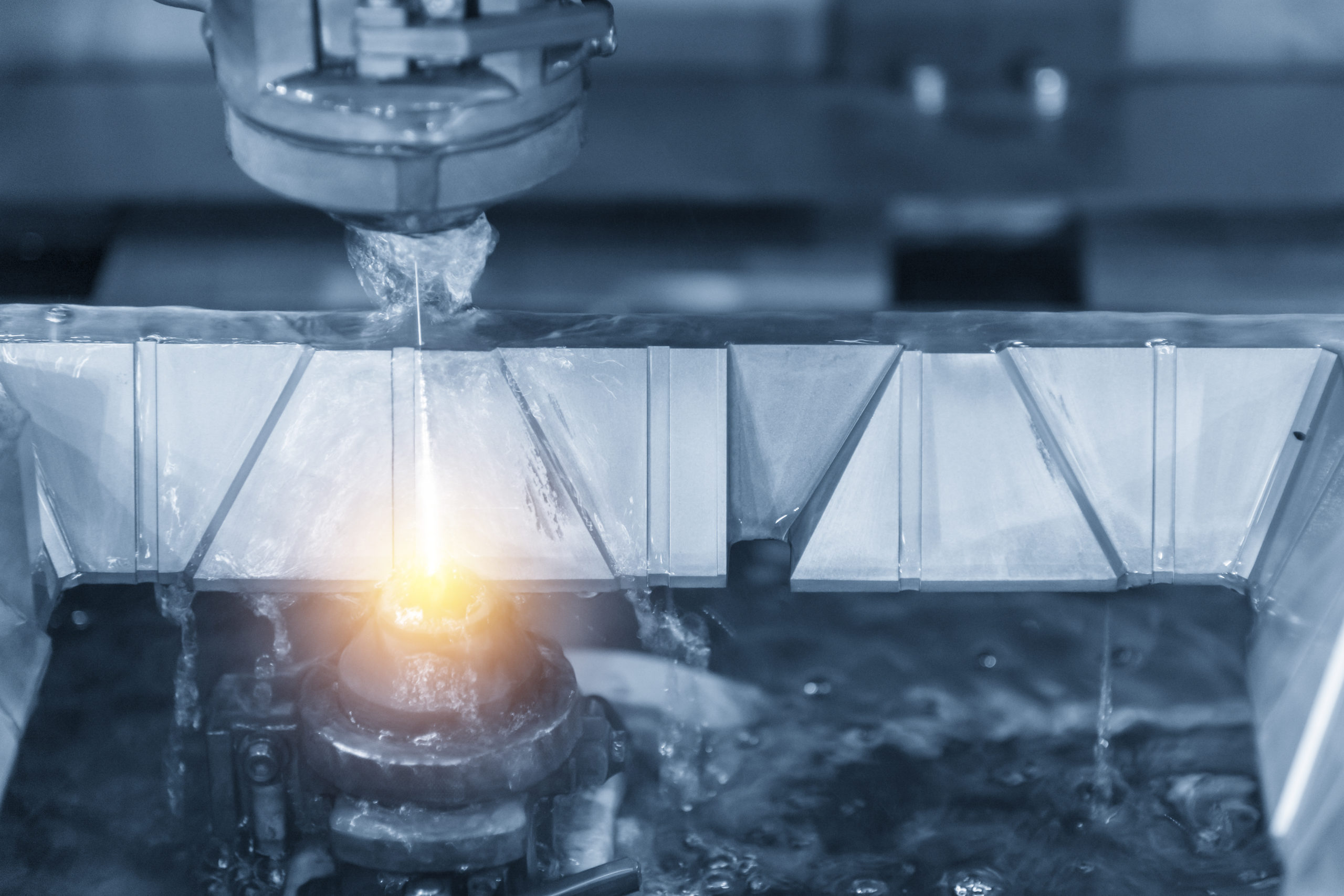

Complex 3-D machining can be accomplished on our 4th and 5th axis equipped CNC Mills such as our UMC 750 5-axis mills and our Fanuc Robodrill Vertical Machining Centers with 4th axis capability. These machines, along with our other 4th and 5th axis equipment, help internal efficiency by reducing the number of operations and in-process handling required to make finished parts. Efficiency can also be achieved through the use of our multiple pallet systems, high-speed spindles, and geared heads that allow us to handle anything from standard steels/alloy steels to exotics.

Our 3-axis and manual milling machines (such as our TRAK FHM7 3 Axis Vertical Mill) also provide our customers with a more cost-effective and delivery-savvy option for small lot production, without sacrificing on quality. These machines are perfect for less complex parts such as base plates, terminal nests, brackets, blades, and more!

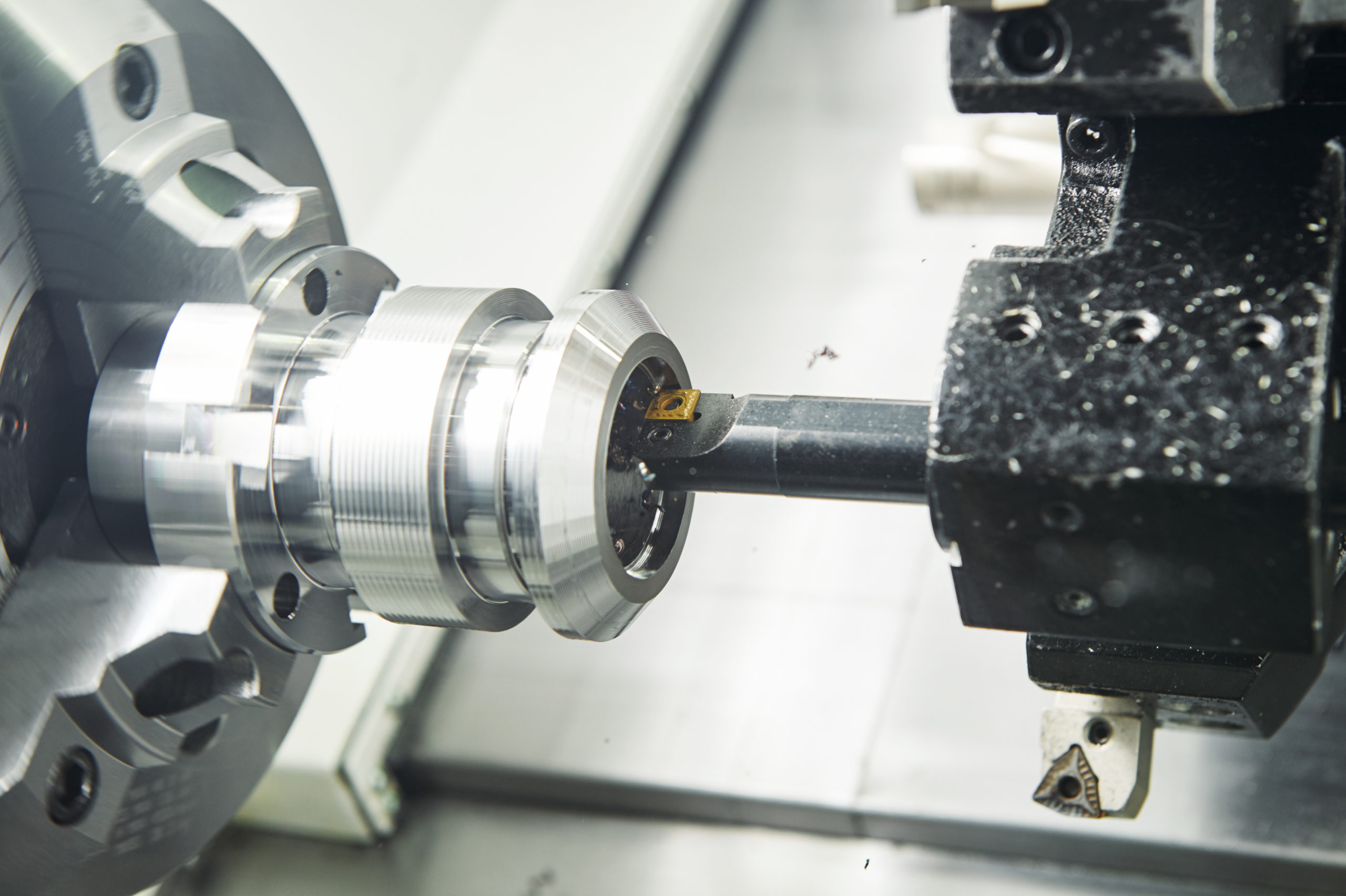

All of Starn’s CNC Lathes have a 10” diameter capacity and a machining distance of 15”, though we are able to handle parts longer than 15” through multiple operations or moving centers. These ultra-precision machines with 12 station turrets are capable of turning materials such as Tool Steel, Stainless Alloys, Exotics, as well as plastic and graphite for electrodes.

We also have two live toolings CNC Lathe machines (Okuma LU 3000 EX and Okuma LB 3000 EX) that allow us to reduce the need for additional milling operations after turning, such as the ability to machine thru-holes, drilled/tapped holes, hex heads, slots, and more, all without ever leaving one workstation. This reduces unnecessary handling between operations and provides a more competitive and comprehensive approach to manufacturing finished parts.

All of Starn’s surface grinders are equipped with digital readouts and have 6” x 18” tables that allow us to run small to large parts with a high degree of repeatability and accuracy on critical surface finishes and tight GD&T callouts. If critical forms are required on parts, we are able to radius, angle, and hand-dress our grind wheels to achieve complex elliptical radii and other intricate forms.

We also have an O.D. centerless grinder to quickly grind tight toleranced, critical surface finish parts like pins, studs, and more!

Through the use of our jig grinder and hone, we are also able to dial-in on critically toleranced I.D. features on various types of parts.

Starn’s Wire EDM machines are able to finish close tolerance, high complexity work with a quick turnaround, especially on high volume production runs as we are able to stack parts or cut multiple parts at a time from a large plate of material.

These versatile machines are efficient for all types of cutting and have 12.6″ x 18.66″ x 4.57″ table travel, and we are also able to taper cut up to 30 degrees.