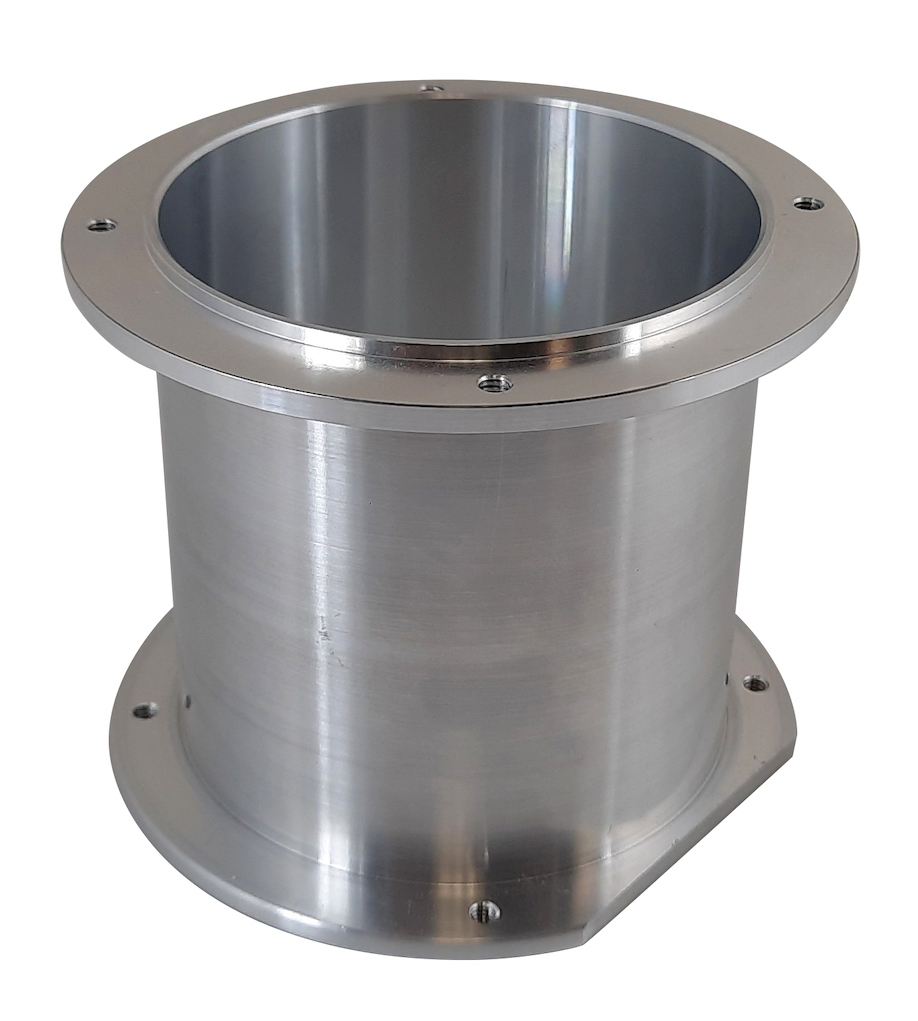

CNC Turning

Experience Breeds Excellence

With nearly 80 years of proven excellence, advanced CNC technology, and inspection equipment, we have the experience and technology to provide high accuracy with high repeatability, even for the most complex parts.

About Our CNC Turning Capabilities

Our CNC lathes have a 10″ diameter capacity for lengths up to 15″. Through the spindle capability up to 3 1/8”. These ultra precision machines with 12 station turrets are capable of turning material such as Tool Steel, Stainless Alloys, Exotics, as well as plastic and graphite for electrodes. Using the CAD/CAM system for programming enables us to turn complex configurations. Our capabilities fulfill a vast customer base in various industries, including automotive, aerospace, robotics, oil & gas, medical device components and electronics industries.

CNC Turning Equipment

- (1) Okuma LU 3000 EX (Turning Center / 10″ Dia. with live Milling with twin turret C axis)

- (1) Okuma LB3000EX live tooling / C & Y Axis

- (1) Okuma LB3000EX-II/500

- (1) Manual Engine Lathe / 10″ x 40″

- (1) Okuma Crown

The Industries We Serve

We machine high & low-volume production orders for customers in multiple industries: Aerospace, Automation Components, Electrical, And Electronic Manufacturing, Government & Defense, Industrial Automation, Manufacturing / Tool & Die, Metal Forming, Oil And Gas, Plastic Extrusion Manufacturing, and Robotics Components

Materials We Machine

– Alloy Steel

– Aluminum

– Brass

– Bronze

– Cold-Rolled Steel

– Copper

– Exotic

Materials We Machine

– Plastic

– Stainless Steel

– Steel

– Titanium

– Tool Steel

– Unalloyed Steel

Quality Assurance

- AS9100D / ISO 9001:2015 Certified

- Inspection report included in every order. Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Strict NDA agreements with all Manufacturing Partners